In an era where manufacturing demands micron-level accuracy and rapid innovation, companies like Precision Technologies International are at the forefront of transforming industries. Advanced manufacturing isn’t just about building products it’s about redefining efficiency, sustainability, and performance in sectors from aerospace to automotive. Precision Technologies International, often referred to in its full legal form as Precision Technologies International Limited or Precision Technologies International Ltd, stands out as a UK-based leader in this space. With nearly six decades of expertise, this specialist in precision gears, splines, and threads is driving the next wave of industrial evolution. Why does this matter? As global supply chains face pressures from geopolitical shifts and environmental regulations, firms relying on high-precision components can’t afford errors. Precision Technologies International’s innovations ensure reliability, cutting costs and boosting competitiveness for clients worldwide. This article explores how the company is pioneering advanced manufacturing techniques, offering deep insights into its impact.

The Legacy and Evolution of Precision Technologies International

Precision Technologies International traces its roots back to the 1960s, when it began as a modest toolmaking operation serving Birmingham’s bustling automotive market. Incorporated formally as Precision Technologies International Limited in 2001, the company commonly known as Precision Technologies International Ltd has grown into a global powerhouse headquartered in Tamworth, Staffordshire. What started with basic hand tools evolved into a sophisticated operation focused on extreme accuracy, thanks to relentless investment in technology and talent.

By the 1980s, Precision Technologies International had relocated to its current state-of-the-art facility, expanding rapidly to meet rising demands. The 1990s marked a pivotal shift: the company entered the aerospace sector, leveraging its high-accuracy services and short lead times to supply critical components. This move coincided with a breakthrough in motorsport, where Precision Technologies International Ltd began producing high-precision timing gears for Formula 1 teams. Today, as Precision Technologies International Limited, it employs cutting-edge CNC machinery and metrology labs accredited by UKAS (United Kingdom Accreditation Service), ensuring traceability to international standards like those from Germany’s PTB.

This evolution reflects a broader trend in advanced manufacturing: from reactive craftsmanship to proactive innovation. Precision Technologies International’s journey underscores the importance of adaptability. In an industry where tolerances can dip below 2 microns far tighter than the human hair’s width the company’s commitment to pushing boundaries has built lasting partnerships with OEMs (original equipment manufacturers) across continents.

Core Expertise: Precision Engineering in Gears, Splines, and Threads

At the heart of Precision Technologies International’s operations lies its unmatched specialization in precision cut and ground gears, custom splines, threads, and gauges. These components are the unsung heroes of advanced manufacturing, enabling seamless power transmission and motion control in high-stakes environments.

Gears, for instance, form the backbone of machinery in automotive transmissions and aerospace actuators. Precision Technologies International Ltd employs advanced CNC gear grinding and hobbing machines to achieve surface finishes that minimize wear and noise. Splines and threads, meanwhile, provide interlocking mechanisms essential for shafts and fasteners in oil and gas drilling rigs or marine propulsion systems. What sets Precision Technologies International apart is its ability to handle bespoke designs, from prototyping small batches for R&D to full-scale production for global fleets.

The company’s metrology prowess is equally impressive. With a fully accredited UKAS laboratory, every product undergoes rigorous inspection using coordinate measuring machines (CMMs) and optical comparators. This ensures compliance with standards like ISO 1328 for gear accuracy and AGMA for quality classes. Deep insight: In advanced manufacturing, where digital twins and AI-driven simulations are commonplace, Precision Technologies International integrates CAD/CAM software to model components virtually before physical production. This reduces material waste by up to 30% and accelerates time-to-market, addressing a key pain point for industries racing toward net-zero goals.

Technological Innovations Driving Advanced Manufacturing

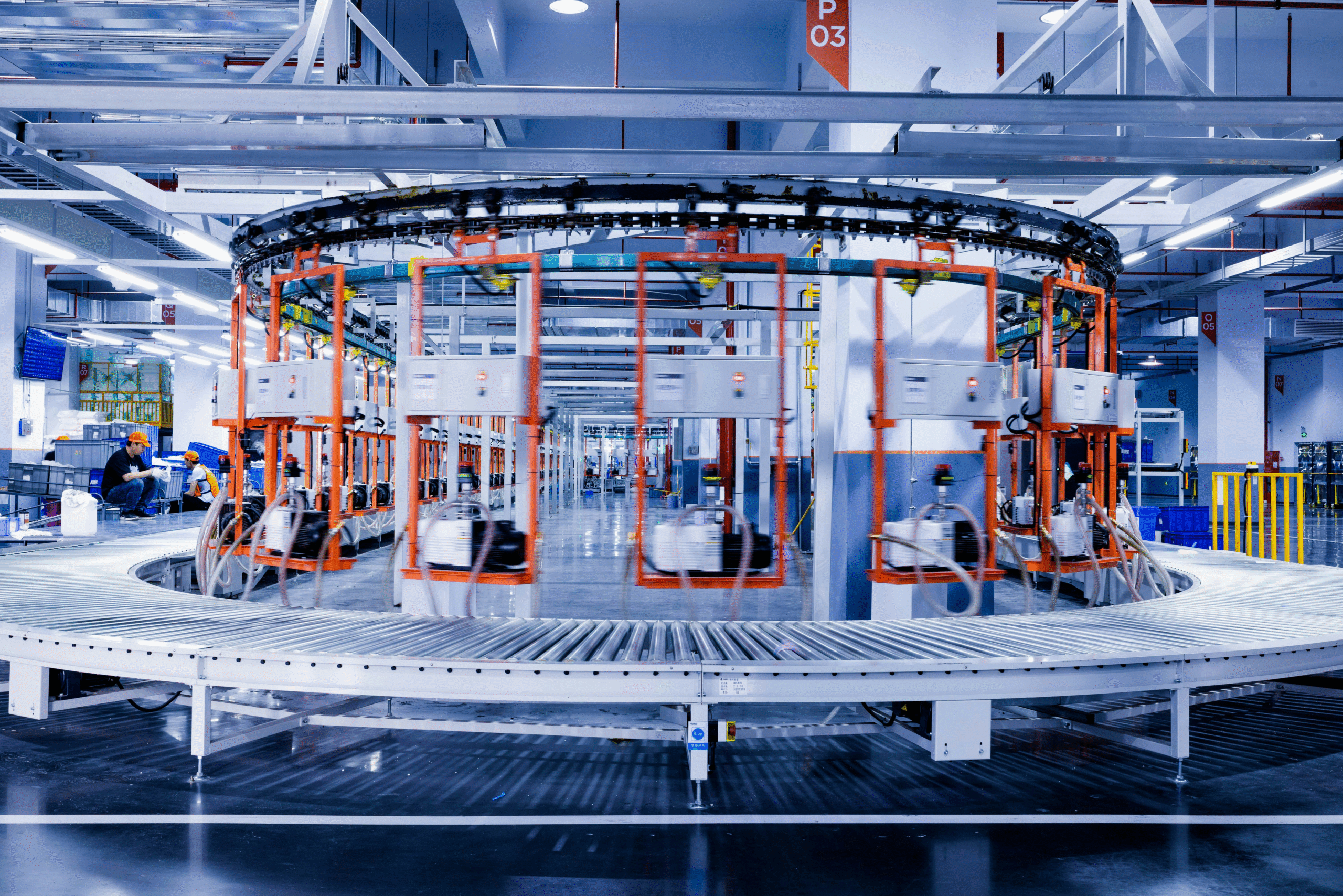

Precision Technologies International is not just manufacturing parts it’s engineering the future through technology. The company’s adoption of Industry 4.0 principles has revolutionized its processes, blending human expertise with digital intelligence.

One standout innovation is its investment in multi-axis CNC machining centers, capable of simultaneous five- or six-axis operations. These machines allow for complex geometries that traditional methods can’t achieve, such as helical splines with variable pitches for electric vehicle drivetrains. Coupled with laser marking and advanced welding, this tech ensures components withstand extreme conditions, like the 1,000°C temperatures in jet engines.

Sustainability is another pillar. Precision Technologies International Limited employs dry machining techniques and recyclable coolants, slashing energy use by 20% per component. Looking ahead, the firm is exploring additive manufacturing hybrids combining 3D printing with traditional grinding to create lightweight, topology-optimized gears. This aligns with broader advanced manufacturing trends, where hybrid processes could reduce aircraft weight by 15%, per industry reports.

A deeper dive reveals Precision Technologies International’s role in digital transformation. By integrating IoT sensors into production lines, the company enables real-time monitoring, predictive maintenance, and data analytics. For clients, this means fewer downtimes and optimized supply chains. In essence, Precision Technologies International Ltd isn’t following trends it’s setting them, proving that precision engineering can be both innovative and eco-conscious.

Industry Applications: From Aerospace to Motorsport

Precision Technologies International’s components power the world’s most demanding applications, showcasing the versatility of advanced manufacturing.

Aerospace and Defense

In aerospace, where failure isn’t an option, Precision Technologies International supplies gears and splines for turbine engines and landing gear systems. Holding AS9100 Rev D certification, the company meets FAA and EASA standards, delivering parts that endure hypersonic speeds and cryogenic conditions. A notable example: custom threads for satellite deployment mechanisms, enabling precise orbital adjustments. This sector alone accounts for a significant portion of Precision Technologies International Limited’s output, highlighting its role in space exploration’s next frontier.

Automotive and Motorsport

The automotive world benefits from Precision Technologies International’s high-performance timing gears, used in luxury EVs and hybrid powertrains. In motorsport, long-standing ties with F1 teams underscore its edge components must survive 20,000 RPM without vibration. Precision Technologies International Ltd’s short-lead prototyping has accelerated R&D for teams like those in the FIA World Endurance Championship, shaving weeks off development cycles.

Oil, Gas, and Marine

For energy sectors, API-accredited thread gauges ensure safe drilling in ultra-deep wells. Marine applications include propulsion shafts that resist corrosion in saltwater, supporting greener shipping via efficient propellers. Across these fields, Precision Technologies International’s precision reduces operational risks, with one client reporting a 25% drop in maintenance costs post-implementation.

These applications demonstrate how Precision Technologies International bridges traditional industries with advanced manufacturing, fostering resilience in volatile markets.

Certifications, Quality Assurance, and Global Reach

Quality isn’t a buzzword at Precision Technologies International it’s a mandate. ISO 9001 certification governs general operations, while AS9100 ensures aerospace-grade reliability. UKAS accreditation for its metrology lab guarantees measurements traceable to global benchmarks, including DIN 3970 and JIS standards.

To illustrate the company’s commitment, consider this comparison of key certifications and their impacts:

| Certification | Scope | Benefit to Advanced Manufacturing | Precision Technologies International’s Application |

|---|---|---|---|

| ISO 9001 | Quality Management System | Ensures consistent processes and customer satisfaction | Streamlines production workflows for all sectors, reducing defects by 15% |

| AS9100 Rev D | Aerospace Quality | Rigorous risk management and traceability | Enables supply to Tier 1 OEMs like Rolls-Royce, with full audit compliance |

| UKAS Metrology | Measurement Accuracy | Traceable calibrations to international standards | Supports sub-micron tolerances in gears, vital for F1 and defense |

| API Licensing | Oil & Gas Threads | Compliance with petroleum industry specs | Facilitates safe, high-pressure drilling components for global rigs |

Challenges and Future Directions in Precision Manufacturing

No leader in advanced manufacturing is without hurdles. Supply chain disruptions, skilled labor shortages, and the push for carbon-neutral production challenge Precision Technologies International. Yet, the company counters these with agile strategies: diversifying suppliers and upskilling via apprenticeships.

Looking forward, Precision Technologies International envisions a future dominated by AI-optimized designs and quantum metrology for even tighter tolerances. As part of the Precision Engineering Solutions group, alongside sister firm Langstone Engineering, it’s poised for expansion into renewables, like wind turbine gears. Deep insight: By 2030, the global precision components market could hit $200 billion, driven by electrification Precision Technologies International is investing in EV-specific tech to capture this growth.

FAQ

What is Precision Technologies International Limited known for?

Precision Technologies International Limited specializes in manufacturing high-precision gears, splines, threads, and gauges for demanding industries like aerospace and motorsport.

How does Precision Technologies International Ltd ensure quality in advanced manufacturing?

Through ISO 9001, AS9100, and UKAS-accredited metrology, the company maintains sub-micron accuracy with traceable measurements and rigorous testing protocols.

In which industries does Precision Technologies International operate?

Key sectors include aerospace, defense, automotive, motorsport, oil and gas, and marine, providing components that enhance performance and reliability.

What makes Precision Technologies International a leader in precision engineering?

Its blend of 60 years of experience, cutting-edge CNC technology, and commitment to sustainability sets it apart, enabling innovations like hybrid additive manufacturing.

Can Precision Technologies International handle custom prototypes?

Yes, the company excels in rapid prototyping for R&D, offering short lead times and bespoke designs tailored to client specifications.

How is Precision Technologies International contributing to sustainable manufacturing?

By adopting dry machining, recyclable materials, and energy-efficient processes, it reduces waste and supports clients’ net-zero ambitions.

Where is Precision Technologies International Ltd located?

Headquartered in Tamworth, Staffordshire, UK, it serves global clients from its advanced facility while maintaining strong ties to regional alliances.

Conclusion: Partnering for a Precision-Driven Tomorrow

Precision Technologies International, through its incarnations as Precision Technologies International Limited and Precision Technologies International Ltd, exemplifies how targeted innovation can reshape advanced manufacturing. From legacy toolmaking to frontier technologies, the company’s focus on accuracy, quality, and adaptability delivers tangible value lower costs, faster innovation, and greener operations. As industries evolve, so does its role in powering them.