In today’s fast-paced industrial landscape, manufacturers face relentless pressure to boost output while cutting costs and maintaining quality. Supply chain disruptions, rising material prices, and the push for sustainability are just a few challenges forcing companies to rethink operations. This is where a manufacturing advisory service steps in a specialized consulting partnership that delivers expert guidance to streamline processes, eliminate waste, and drive sustainable growth.

A manufacturing advisory service provides tailored strategies from seasoned experts who analyze your operations and implement proven methodologies like lean manufacturing and digital transformation. These services go beyond quick fixes, helping businesses achieve long-term production efficiency gains, often resulting in 20-30% cost reductions and faster time-to-market. With global competition intensifying, partnering with a manufacturing advisory service isn’t optional it’s essential for staying ahead.

What Is a Manufacturing Advisory Service?

A manufacturing advisory service is professional consulting focused on optimizing industrial operations. It combines strategic advice, technical expertise, and hands-on implementation to address inefficiencies in production, supply chains, and overall business performance. Unlike general business consulting, these services are tailored specifically for manufacturers, drawing on deep industry knowledge to tackle sector-specific issues like equipment downtime, inventory overload, and regulatory compliance.

Historically, programs like the UK’s Manufacturing Advisory Service (MAS) set the standard. Launched in 2002 by the Department of Trade and Industry, the MAS Manufacturing Advisory Service supported SMEs with free reviews, funded improvement projects, and supply chain guidance. Though the government-funded version closed in 2016, its legacy lives on through private providers and relaunched initiatives that continue offering signposting, process optimization, and growth support.

Today, a manufacturing advisory service encompasses operational audits, technology integration, and sustainability planning. Firms like TCS, BDO, and Bain & Company lead globally, helping clients adopt Industry 4.0 tools for smarter factories.

What Is the MAS Manufacturing Advisory Service?

The MAS Manufacturing Advisory Service originated as a UK government initiative to bolster small and medium-sized enterprises (SMEs) in England and Scotland. Founded in 2002, it provided technical and business advice, funded reviews, and grants up to £10,000 for strategic changes. Delivered by consortia including Grant Thornton and Pera, the MAS focused on four pillars: strategy, innovation, efficiency, and supply chain connections.

Key offerings included:

- Free on-site business reviews and action plans.

- Match-funded projects for process improvements.

- Supply chain diversification into advanced manufacturing.

The program delivered impressive results, with participating companies seeing up to 30% productivity gains and 37% waste reductions in its early years. Despite closure in 2016 due to austerity measures, MAS was relaunched privately in 2017 by industry groups like Made in Midlands, focusing on signposting and peer support without grants.

Globally, similar services exist under programs like NIST’s Manufacturing USA network, which fosters innovation institutes for advanced manufacturing. The MAS Manufacturing Advisory Service remains a benchmark for how targeted support can revitalize manufacturing sectors.

What Is the Purpose of Advisory Services?

The core purpose of advisory services is to provide expert insights that help organizations make informed decisions, solve complex problems, and achieve strategic goals. As defined by the AICPA, these services involve developing findings, conclusions, and recommendations for client action.

In manufacturing, this translates to bridging gaps between current operations and optimal performance. Advisory services aim to:

- Enhance profitability through cost analysis and process optimization.

- Mitigate risks in supply chains and compliance.

- Drive innovation via technology adoption and workforce development.

Ultimately, the purpose is empowerment equipping leaders with data-driven strategies to navigate market volatility and foster sustainable growth.

What Comes Under Advisory Services?

Advisory services cover a broad spectrum, tailored to client needs. Common areas include:

- Strategic Planning: Market analysis, business modeling, and growth roadmaps.

- Operational Improvement: Lean principles, process reengineering, and efficiency audits.

- Financial Advisory: Budgeting, forecasting, tax planning, and cost management.

- Technology Integration: ERP implementation, IoT, and digital twins.

- Risk and Compliance: Cybersecurity, regulatory guidance, and sustainability strategies.

- Human Capital: Training, leadership development, and change management.

In manufacturing, these often overlap with specialized tools like Six Sigma for quality control or supply chain analytics for resilience.

What Are Manufacturing Support Services?

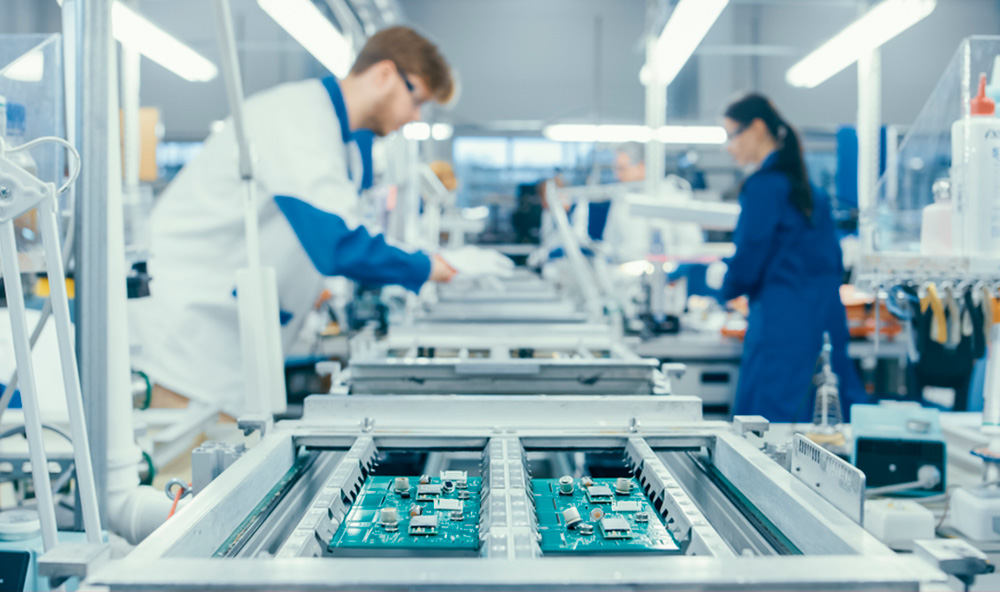

Manufacturing support services complement advisory by providing logistical and operational backbone. These include third-party logistics (3PL) for inbound materials, kitting, sequencing, and quality inspections.

Key examples:

- Inventory management and just-in-time delivery.

- Sub-assembly and packaging.

- Facility layout optimization and automation support.

Unlike pure advisory, support services are hands-on, often reducing lead times and capital expenditures while freeing manufacturers to focus on core production.

How a Manufacturing Advisory Service Boosts Production Efficiency

A manufacturing advisory service transforms efficiency by identifying bottlenecks and deploying targeted interventions. Experts use tools like value stream mapping to eliminate waste, achieving 20-50% reductions in cycle times.

Core mechanisms:

- Lean Implementation: Streamlining workflows to minimize downtime and overproduction.

- Digital Tools: AI-driven forecasting and predictive maintenance.

- Supply Chain Optimization: Enhancing visibility for just-in-time inventory.

Results? Companies report higher OEE (Overall Equipment Effectiveness), lower costs, and improved competitiveness.

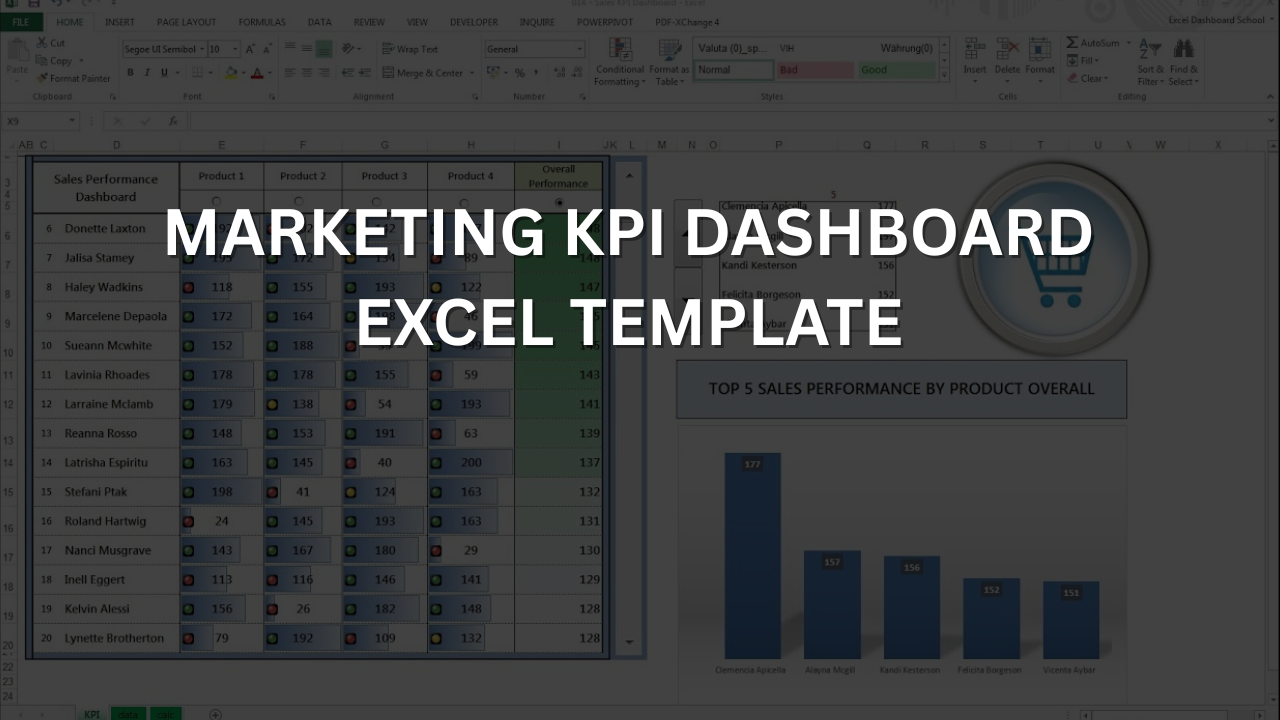

Key Benefits of Manufacturing Advisory Services

| Benefit | Description | Typical Impact |

|---|---|---|

| Cost Reduction | Process optimization and waste elimination | 20-30% lower operational expenses |

| Increased Productivity | Lean tools and automation | Up to 30% higher output |

| Improved Quality | Six Sigma and defect tracking | Defect rates drop by 50%+ |

| Supply Chain Resilience | Diversification and real-time analytics | Reduced disruptions by 40% |

| Sustainability Gains | Energy-efficient practices and circular economy models | 20%+ lower carbon footprint |

| Faster Innovation | R&D acceleration and new product introduction | 25% shorter time-to-market |

Real-World Case Studies: Success Stories

One UK manufacturer used MAS-funded projects to redesign layouts, boosting productivity by 25% and creating 50 new jobs. Globally, Bain helped a robotics firm implement lean, slashing costs by 30% through reorganization.

Another example: A U.S. electronics company partnered with Panasonic’s lean consulting, reducing WIP and improving flow via pull systems. These cases highlight ROI—often 3-5X within months.

Choosing the Right Manufacturing Advisory Service

Look for providers with proven track records, like McKinsey, BCG, or specialized firms such as Cultivate Advisors. Prioritize those offering end-to-end support, from audits to implementation.

FAQ

What is the purpose of advisory services?

Advisory services deliver expert recommendations to improve decision-making, efficiency, and growth, focusing on strategic, operational, and financial challenges.

What is the MAS Manufacturing Advisory Service?

It was a UK program (2002-2016) providing funded advice to SMEs; now evolved into private services for process and supply chain improvements.

What comes under advisory services?

Strategic planning, operations, finance, technology, risk management, and HR development.

What are manufacturing support services?

Logistical aids like 3PL, kitting, and quality control that support core production.

How quickly can a manufacturing advisory service deliver results?

Many see initial gains in 60-90 days, with full transformations in 6-12 months.

Are manufacturing advisory services worth the investment?

Yes—typical ROI is 3-5X, with sustained efficiency improvements.

Can small manufacturers benefit from these services?

Absolutely; programs like the original MAS targeted SMEs for accessible, high-impact support.

Conclusion

A manufacturing advisory service is a game-changer for production efficiency, turning challenges into competitive advantages through expert guidance and proven strategies. From legacy programs like the MAS Manufacturing Advisory Service to modern global leaders, these partnerships deliver measurable results in cost, quality, and speed.